Guest Post by Hardscrabble Farmer

A couple of months before I left the US Army I was offered a course in carpentry as pat of my out processing. I’m not sure if they still do this for enlisted personnel, but for the cost of serving an additional 3 months- voluntary extension was the term- it has paid me back in ways I cannot begin to calculate. The first project in that class was to build a carpenter’s toolbox from a blueprint to hold a basic set of tools; three kinds of saws, chisels, screw drivers, hammer, etc. We built them from pine sold to us by the civilian instructors and in a few days we each had one of those old timey looking carpenter’s boxes ready to be loaded up with the implements of our future trade.

In the thirty plus years since then I have used tools on a regular basis both professionally and as a homesteader. I’ve framed and finished, done form work for concrete, laid tile and shingled. I can hang doors and build stairs, build cabinets from scratch and hang and finish sheetrock. I’ve done most everything else as well from basic plumbing and electrical work to installing HVAC and septic fields. I’m handy with excavators and I’ve hung iron. Beyond that three week course at the end of my stint in the military, most of which was spent converting the instructor’s carport into a family room, I have no formal training. I’ve learned that the vast majority of tasks that seem difficult aren’t, that things which look like they require advanced skills merely demand attention to detail and a desire to do the job properly.

As daunting as it may seem to most people, it is one of the most rewarding and yes, joyful experiences in life; to build something with your own two hands whether it is a dog house or a lake house. Human beings are designed to make and use tools and though I have heard people frequently comment over the years that they are ‘all thumbs’ or ‘not good with tools’, even a few minutes of supervised demolition or rough carpentry projects will dispel that notion. Of course there are those who simply do not enjoy it, but that doesn’t prevent them from doing what is necessary to repair something simple with nothing more than a few tools and their own hands, often at an enormous savings when you consider the hourly wage of a skilled carpenter these days.

I have long since lost track of the wooden toolbox I built in that class only to replace it with a series of other containers for my hand tools. I now use a five gallon plastic pickle bucket with a nylon tool sleeve I picked up at a hardware store several years ago. The larger tools fit in the center section while the smaller tools fit in a series of pockets arranged around the outside edge. The number of tools I use frequently could easily fit in a tool belt and are kept there, draped over the bucket ready to use, while the rest of my set are arranged, well oiled and sharpened in the bucket. This is a list of those tools for anyone who may interested.

A good tool belt. This is a basic no one should be without. Mine is made of rough leather with four pockets and a special compartment centered between the two for a tape measure. The belt itself is an old army style web belt that can be adjusted easily. There are belts with suspenders and others with multiple pockets for nails and tools, but most of these are specialty types for framers and roofers. Find what’s comfortable, that’s key.

A solid tape measure, 30′ is a good size. A tape measure should have at least a 3/4 inch blade that retracts and locks. I use standard measure (feet and inches and fractions of inches to 1/16. Canadian carpenters I run into use metric. Be sure you get what you’re used to and learn how to read it. A good carpenter measures twice, cuts once and it always helps to say the measurement out loud or write it in pencil on the piece you’re about to cut. When you cut make sure to leave the pencil mark visible on the piece you are planning on using. A piece a little bit long can always be trimmed, but one cut short cannot be stretched back. I also carry a fifty foot tape for laying out larger buildings, but it is by no means a necessity.

A square. I prefer a steel speed square, some people like the lighter plastic ones, other the old style framing square. There are advantages and disadvantages to each. Framing squares feature formulas for cutting risers for stairs and determining pitch on roofs, something most beginners will not be able to do without. The same functions can be done with a speed square once you’ve learned how to determine rise over run and it fits in your pouch. The framing square takes up a lot of room and usually remains at the cutting table. If you drop a plastic one onto a concrete floor from the rafters, it will break every time.

Carpenter’s pencil. Flat so they won’t roll off whatever surface you lay it on, heavy graphite so the mark shows up on whatever material you happen to be using. I long ago made a lanyard to wear the pencil around my neck (nothing is more frustrating than having to climb down a scaffold to retrieve a dropped pencil half a dozen times a day. I simply cut a piece of parachute cord about 24″ long and use electrical tape to wrap around the pencil and two ends of the cord. Should it ever get caught on something the cord will pull out of the tape easily, the rest of the time it hangs right where you need it.

Hearing Protection and Safety Glasses. ‘Nuff said. Wait, I forgot to add that at my age the safety glasses with built in magnifiers are the bomb.

Utility/Razor Knife. I prefer a retractable, some folks like the fixed blade (too dangerous) others the quick change (too complicated). Extra blades should be kept in the body of the knife and blades should be changed regularly. WARNING: this is the single most dangerous tool you will ever use, bar none. I have a permanently bent left index finger from cutting through the tendon to the bone with a utility knife. I watched a carpenter score a piece of sheetrock with a utility knife along the edge of a T-square. About halfway up it hit a nick in the aluminum and continued across the square and directly up his leg about six inches exposing muscle and bone. Dan-ger-ous. Always be aware when you use this tool, always.

Screwdrivers. Screw guns have almost replaced these hand tools in most cases, but I can’t tell you how important it is to have at least three of each flat tip and phillips. One long and standard sized, one short and standard, one small tip. You’ll use the small phillips regularly to change utility knife blades and the regular flat tip to take off electrical outlet covers.

Chisels. I keep about four or five in sleeves, well sharpened. One wide one (3″), one medium (1 1/2″), one half inch and a couple of cold chisels.

Rip/Crosscut Saw. There are plenty to choose from, again a poor substitute for a 7 1/4″ power saw, but indispensable for certain tasks and always greatly appreciated when nothing else will work. I have a short one- a sixteen inch blade- and it has served me well over the years. Kept sharp it is invaluable.

Hack Saw/Keyhole Saw/Coping Saw. For metal, sheetrock and trim respectively.

Hammers. I once preferred a 32 ounce Eastwing waffle faced framing hammer but my elbows are too worn out to swing that hammer any more. These days I use a smooth faced 22 ounce hammer for virtually everything and carry a small sledge for heavier tasks. A tack hammer is another option, but certainly not a necessity. With hammers ergonomics is key; does it feel right in your hands? Is it balanced and are you able to swing it with ease? Then it’s perfect for you. A mallet is also a good idea for when you want to smack the hell out of something and not leave a mark. Not necessary, but nice to have as a persuader.

String. A good ball of heavy duty nylon string will last a lifetime and can be used for hundreds of tasks. No tool kit is complete without one, from establishing footings and foundations to leveling across uneven ground string is the thing.

Levels. I carry a four foot level on it’s own, but it accompanies the bucket everywhere so I include it here. A small spirit level between six and eight inches in length can easily be substituted simply by fastening it to a length of lumber to extend the leveling surface. A line level is small and can be used on a string with effectiveness for longer runs.

Folding Rule. This is one I carry in a side pants pocket every day. Along with a knife and a pencil these are the only tools I never leave the house without. I know plenty of carpenters who don’t even own one and who have never used it deferring to the tape measure, but carrying a tape measure everywhere is cumbersome and the folding rule is not. It can be used for fine measurements, like sizing hardware or interior spaces- the width of a door or window. A good one has a small brass six inch extendable rule for using as a depth gauge for tight space like lock sets, drawer depths, etc. It’s also the hands down favorite tool of every child I have ever met. They are endlessly fascinated by it’s clever hinge system that allows a six foot measuring device to fold up into a six inch block.

Adjustable Wrenches. I carry two, one large, one small because sometime the nut is large and sometimes it’s not and every once in a while you’ll come across two opposing nuts that require opposing forces of torque to unfasten. I cut the end of of my larger adjustable and welded a 5/8″ box wrench sized for the nut on my 7 1/4″ power saw to change blades quickly.

Vise Grips, Pliers, Wire Cutters, Needle Nose Pliers. One of each suffices for most everything, however you may find yourself pining for more than one vise grip in either a larger or smaller size than whichever one you initially choose because they come in so darned handy when you find something that’s been frozen by rust, something that needs to be compressed back into shape, etc. I must have collection for any tool box.

Allen Wrenches. A set of these should include both metric as well as standard and these days you can get a nesting set with built in holder that contains them neatly. There were years when I never came across a need for these tool, but lately most pre-fabbed furniture sets- think Ikea- are based entirely on allen systems for fastening. If you do even a small number of mechanical jobs, like maintaining chain saws or working on small engines, they’re a necessity.

Chalk box/plumb bob. Again a tool you won’t use all that often unless you work with sheet materials like plywood and sheetrock but which makes marking long runs possible even for hack with shaky hands. The chalk box doubles as a plumb bob- the most accurate tool for assuring something is straight up and down, but I still carry an iron one that’s been in my family for generations and just looks sweet. On the occasions when I’ve pulled it out for use- once we were placing floor anchors 20 feet below the timber frame of the hay barn and they had to be precise- I always get compliments from other tool type guys about how archaic and totally wicked it looks.

Flat Bar, Cat’s Paw, Glazing Bar. The essential demo kit, used for pulling nails, taking apart structures, adjusting and prying multiple materials. I recommend titanium as opposed to tempered steel because they last longer and perform better in the long run for a marginal difference in cost.

Rancher’s Pliers. It’s a hammer, pry bar, wire cutter, nail puller and pliers all in one. Essential if you ever build or repair fences or enclosures.

Clamps. Two C-Clamps, two spring clamps, two shorty bar clamps. If you work alone these serve as a second set of hands and if you are using adhesives these will keep your pieces fixed securely until the glue sets. Pipe clamps are handy as well, but they belong in the shop.

Nail Sets, Steel Punches. For setting nails beneath the finished surface and removing metal items locked in place.

T-Bevel. Used to trace or replicate angles in fixed objects for duplication.

Files/Rasps/Whetstone. I carry one of each, a flat metal file, a wood rasp and a stone for sharpening tools on site.

Compass. For marking circles and arcs. The tip can be used in place of an awl for marking points in material.

Tin Snips. For soft metals like aluminum and copper and the ultimate tool for cutting nylon and metal banding on materials.

Plane. I carry a small block plane for finishing surfaces to close tolerance or chamfering edges of heavily used areas like doors and windows.

Paint Brush. I use this for cleaning out sawdust, debris in areas where I am working and for removing dust or waste. Beats wiping things off with your hands and winding up with a splinter.

A Good Rag. Heavy duty cotton rag is great for a multitude of tasks from wiping down finished surfaces to cleaning tools. Doesn’t take up much room and if sprayed with a little WD-40 serves as a way to prevent rust when it is humid or if your kit gets hit by a little rain.

Ratchet Set. Another kit that should include both metric and standard sockets, a large and a small handle, and an extension.

I have been able to refine this set over the years based on the types of jobs I have done and have added and dropped tools on occasion based on weight -no one needs a crow bar- and the appearance of multi-tools that replace two or three others just as effectively. I plan on doing an essential power tool list in the near future because in this day and age using something like a bit and brace in place of a lithium battery powered drill is absurd and deliberately neo-luddite. I’m not that guy.

I have just one tool. Works great, too! ?w=350&h=200&crop=1[/img]

?w=350&h=200&crop=1[/img]

[img

Excellent list, very comprehensive. Hardly anything I’d add, except a roll of electrical and/or duct tape, channel-locks, and electrician/lineman pliers (that may be what you meant by “pliers”).

And I second the warning about the utility knife – I have a large scar (also on an index finger, fortunately without the permanent bent) from trying to use a hook-bladed razor knife to carry a sheet of drywall – another tip, don’t try and emulate what you see the “pros” do, it’s quite often not all that professional…

Oh – and I’d fire any carpenter who doesn’t have or use a folding rule. Just my opinion…

Not to rain on your parade, HS, but there’s loads of stuff you’re missing and/or missing out on… I understand there’s restrictions because of limited space, but then, there’s toolboxes…

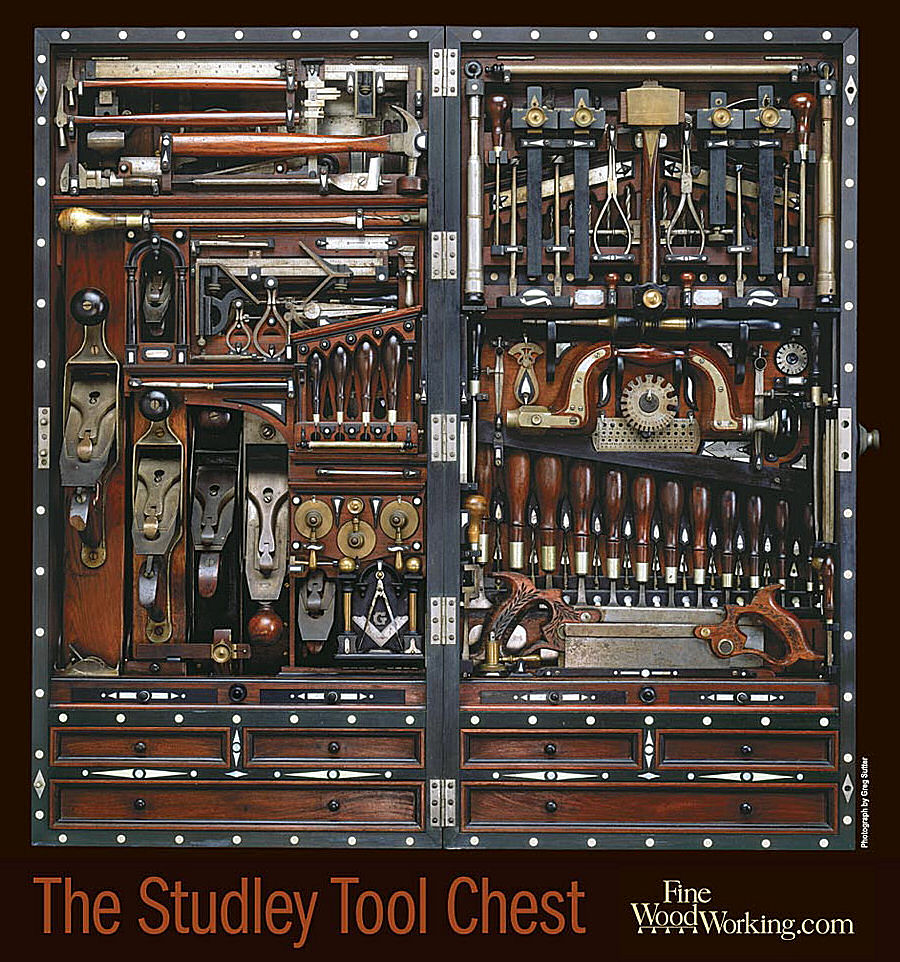

And there’s toolboxes…

[img [/img]

[/img]

Fine Woodworking offers the plans to build this box (as well as others). I obtained a set, but have not dedicated the time to build one yet…

One of these days, I’m gonna have to make a list of tools… there’s all sorts of stuff I consider “indispensable”, and not all tools are created equally… a chisel you buy in some big box store is what I would call a “shit chisel” – schlocky peanut butter steel that barely holds an edge, but is used when the chances of hitting a nail are good. No way in hell would I risk a high-end chisel like that.

Meh.. I could drone on for a long time about the correct way to sharpen a cutting edge, how to care for tools, why “user-made” tools are generally better than store-bought ones, how many different kinds of saws there are and how to sharpen them properly, different kinds of planes and why they’re better than routers, why square cut nails are better than round wire-cut nails, why joining two pieces of wood together mechanically will always be better than spiking them together with nails, how to mix finishes, which finishes are better than others (and which suck ass)… blah, blah, blah…

By the way… if anyone comes across a Stanley No. 1 hand plane at a yard sale or antique store for reasonable money – the genuine article – I’d be much obliged if you’d give a shoutout… not that I “need” the thing, but it would complete the set…

Stanley No. 1 Smooth Plane

Manufactured:————— 1869 to 1943

Length: ———————— 5-1/2 inches

Blade Width: —————– 1-1/4 inches

Construction: —————- Cast iron, rosewood handle & knob

Finish: ———————— Japanned

Features: ——————— Extra small

Uses: ————————- General purpose bench plane

Average Dealer Price: —- $1000 to $1600

Average eBay Price: —— $1200 to $1800

Type 1: ———————— $1600 to $2800

Type 2: ———————— $1400 to $2000

Type 3 to 12: —————– $1200 to $1800

Counterfeit version: ——— $150 to $300

Other Notes: These planes are not marked with a number cast into the bed and had no lateral adjustment lever. The trademark is stamped on the blade only. Sweetheart versions (1920-1935) often reach higher prices, but not always.

The counterfeit planes have a much rougher body, frog and lever cap casting, as well as badly shaped handles. The rear screw for the blade adjustment tilts upward rather that straight back. The blade is often stamped on both sides

==============================================================

TOOLS AND TOOL COLLECTING

The lovable little Stanley No. I

“Stanley tools represent a major category of collectible tools, and can form the basis for a rewarding and stimulating hobby. One of the most desirable of Stanley tools for the collector is the diminutive Stanley No. 1 bench plane. This tiny, 5-1/2” long plane poses some interesting mysteries for the collector. First, what was it used for? It’s so small-that even a craftsman with a small hand finds it uncomfortable to use. And second, for a tool that was manufactured in abundance over a 73 year period (1870-1943), why should it be so scarce?

As to the first mystery-its size-the explanation is relatively straightforward. These planes were designed for use by elementary school woodworking classes, and were used in the introduction to the proper care and use of woodworking planes.

The second mystery requires a more hypothetical explanation. With the advent of U.S. involvement in W.W. II came the need for scarce raw materials by factories involved in the rapidly increasing war production industries. Those with memories reaching back that far remember that not only were civilians in general involved in paper and fat saving drives, among others, but schools and other institutions also were called on to collect and donate large amounts of scrap material.

The widespread draft also was a factor. Shop teachers, especially at the elementary school level, came into short supply overnight, thus freeing up the tools and materials formerly used in their courses as vital scrap. Since the majority of No. 1 planes produced were to be found in schools, a large number of these planes were absorbed by the wartime scrap drives.

In case you’re thinking of purchasing a Stanley No. 1, be prepared to pay between $400 and $650 for an example in good or better condition. Also be sure to buy from a reputable dealer who will guarantee the plane is genuine.”

——————————-Wood Magazine issue No. 1 Sept/Oct 1984.

Yeah, I know you said “reasonable”. Good luck! Several on Ebay …. ranging from $800 – $1300

http://www.ebay.com/itm/Stanley-No-1-Sweetheart-Smooth-Plane-Hand-Plane-/191216016526

HF, Would you consider writing an article about your thoughts on the prevelance of tattoos in today’s society and what they might mean to the “wearers” spiritual condition? I have my own thoughts on this as I’ve observed the creep of this phenomena over the years, but I’d love to hear what you think. Thank you sir!

Yeah Billy,

They are shit chisel and they are good for shit jobs. I have four or five wonderful chisel, but don’t use them much. I would not us a fine chisel to pound out grout and such. I use the crappy chisel on anything from silicon chalking to grout /tile.

I find it amusing that most men can’t build a fence, and with the products available today, it is a breeze.

Some professional carpenter wants to sell all this for $10 …. posted on Craigslist one month ago

[img]https://s1.yzimg.com/000fto2vcujhdnqu.640×480[/img]

https://us.yakaz.com/posts/0002o3p4ra5uel20

Lastly, Billy, maybe you can find some success with this …

“The purpose of this blog is to provide folks like me with a little useful info about planes and to connect those who are searching for decent planes with, well… decent planes.”

here

http://hand-plane-tool-hunter.blogspot.com/

See that just goes to show you can always find another tool or piece of equipment that you don’t have that you need. Even off of HSF short list of basics he has one item that I don’t have that I truly need, Safety glasses with built in magnifiers. Where do you get them I don’t think HD carries them?

Here you go-

Bifocal Safety Glasses

I have the plane, not giving it up for any amount of money.

What? $1000 for an old plane, AYSM? I had no idea old tools had that kind of value.

Years ago at an estate sale I bought a large wooden box full of old woodworking tool, chisels and planes and that type of thing. OK where did I put all that stuff?

@ Stucky,

Damn speculators and collectors…

I don’t collect tools… I use them. Craigslist Guy has 5 braces in that photo and one eggbeater drill, but I don’t see any bits.. what looks like half a set of hollows and rounds.. the block planes caught my eye – there might be a diamond in there somewhere. Chalk lines, squares, keyhole saw… normal stuff.

About the best hand saw you can get these days is made by Lynx in England. One good saw will run you about $250 bucks or so, but they make rip and crosscut both, as well as coarse and fine cut saws… they come with this varnish stuff coating them to protect the steel, so you have to use something like gasoline or another solvent to get rid of it, then wipe it down with an oily rag. Best to remove the handle before you do that… if you don’t remove the varnish coating, it will bind when you try to make a cut. The varnish heats up via friction, then gets sticky, which makes it difficult to cut. Plus it looks like shit when it gets all scuffy… best to remove it.

There’s all kinds of saws… Crosscut, rip, dovetail, tenon, razor, flush-cut, stair, progressive pitch, inlay, turning, keyhole, back saw, etc… each has it’s job and no, one saw cannot do everything… then there’s Japanese saws which cut on the pull stroke, not the push…

Sometimes – and it’s rare, because saws usually get used up pretty good – you can find a Disston saw from the 20’s to the 40’s come up for sale… the older ones were more ornate and had more variety with regards to pitch, blade length, handle shape and type of wood used, so they usually cost more… but, they are sooooo worth it.

A Garlick & Son “Lynx” rip saw…

[img [/img]

[/img]

A trio of our finest… the Holy Grail – a mint Disston No. 12, and a pair of brass back saws (though I would probably call the bottom one a dovetail or tenon saw… have to see the teeth first)

[img [/img]

[/img]

I mean, LOOK at that big bitch! That No. 12 rip saw makes modern saws look like fuck-all, doesn’t it? Makes them look like what they are – pieces of cheap shit stamped out like bottle caps… it wasn’t just a useful tool, it was functional art…

I have the plane, not giving it up for any amount of money. – HS

I don’t blame you. I found a cache of planes at my Grandfather’s house a few years ago. Buried in the back of an old cabinet were several Stanley hand planes. A Number 2, one Number 3 and two Number 4’s…

I just want a Number 1 to complete the set… (says the guy who doesn’t “collect” tools.. .heh) I’ve got them all the way up to 8. Only one missing, is a 1. I’ve also got a matched set of tongue and groove hand planes (1/2 and 1/4), couple different combination planes, beveling planes, block planes, rabbet, all sorts of planes… .even a halfway decent (incomplete) set of hollows and rounds…

@ Stucky,

Over at Patrick’s Blood and Gore, he covers just about everything Stanley ever made… and he’s funny as shit, too… required reading for anyone wanting old tools…

http://www.supertool.com/StanleyBG/stan0a.html

@ Welshman,

Tell me about it…

The worst is when you see a fine tool that’s been abused…

Like the socket-head chisel. Usually comes with a hornbeam or boxwood replaceable handle. Almost nobody makes them anymore, and those who do want an arm and a leg…

Many times I’ve come across a good quality socket head chisel – like a Stanley 750 – where the handle is missing, but instead of fabbing a new handle, the previous owner just pounded on the socket and mushroomed it, ruining the chisel forever….

There’s a special place in hell for people like that…

A pair of channel locks should go in the bucket. Misc. nails, screws, nuts, bolts., washers. Faucet washer or two. Duct tape. Good string. Electrical tape. Hose fittings. C clamps.

General personal preference on a lot of stuff, but HSF’s list is pretty good.

Meant hose clamps not c clamps above.

Or you could just go to Sears and buy a quality tool box for about 100 dollars.One thing I like about my tool box is it will never burn ,break or come unglued.I put all my tools in a storage unit . Now I put ammo and loaded magazines in my tool box.Go figure.

Hand tools are like iron sights. Two weeks after TSHTF the guy with the iron sights rules as will the guy with the hand tools. Grandpa had hand tools and knew how to use ’em. The family doesn’t give a shit about the old augur set, or the saws, or the chisels, &TC. Many of these can be had for a song at garage sales or estate auctions. At one point, my father built, by hand, mostl of the furniture in our house. Tables, chairs, and other pieces made by hand with hand tools. His first electric tool was a Skil circular saw. I still have it and it works like a champ! Electric/electronic stuff is wonderful, but shit fails and batteries run out. Mechanical backup is a very desirable option and it’s fun to check out the yard sales and auctions.

My dad is a tool buff, and still kicking at 80. He does not understand me or the concept that my guys wear out tools. It pains him to watch them throw stuff around, not grasping that a flat shovel scraped against concrete every day only has a life span of about a year, and cutting tools sharpened with a grinder daily only last so long.

He was convinced that his 30 year old skil saw was the only one he would ever need, until he borrowed one of mine, and discovered blade guards, and safety triggers and laser guides. HSF, great list, and that list is classic. You are all man, swinging a 32 oz hammer.