Guest Post by Hardscrabble Farmer

The bucket list of essential hand tools for the self sufficient life got a lot of positive feedback. It wasn’t designed for carpenters specifically, but for people who prefer to handle most of their own construction, repairs and homestead maintenance using their own two hands. Looking back on that list I came across some missing pieces, like putty knives, a set of micro screw drivers and channel locks, but in general it covered most everything you could ever need and it all fits in a single five gallon bucket- sweet!

What I did not cover, and the purpose of this list, is the primary power tools that would make it possible to complete virtually any project up to the size of a home or barn. I realize that while the first list could easily be put together for under a thousand dollars if each item were purchased brand new, most people either have a good start or could complete it with a couple of visits to local yard sales or a quick glance through craigslist for less than $200, not bad for a lifetime of self sufficiency, tool-wise.

To put together the following list requires both a broader skill set, more room and a considerable investment, especially if purchasing these tools in factory packaging. Locating them via second hand options provides a bigger challenge, especially considering manufacturer preference and size/age/condition. The former would likely run somewhere between $5-$7,000, the latter in the $2-$3,000 range a not inconsiderable investment. For those reasons alone I recommend that anyone interested be willing to consider if the long term plans for use would be worth the short term expense.

Since I don’t want to either promote or push any specific brand, suffice it to say that the most important consideration is how well the tools hold up under frequent use and how they ‘feel’ to the user. Over the years I have used virtually every brand available and my personal favorites are different for each tool; Makita makes the best Drill/Drivers, DeWalt the better table saw and miter saw, Milwaukee the best sawzall and impact tools. These determinations have been based on years of constant use, ergonomics, design and durability, etc. I suggest trying each tool out if possible and getting your hands around them at the very minimum.

1) Battery Powered Drill/Driver. The sheer variety of uses for this set, the portability of a battery powered versus AC powered and the long life of lithium batteries these days make this set one of the most frequently used tools on the farm. I switched over to GRK fasteners a few years back and these heavy duty screws offer an upgrade over phillips head in much the same way phillips replaced slotted screws. They are reusable, structural quality and impossible to strip. The down side is the cost (usually 2-3x) but in terms of longevity and holding power they rock. Keeping batteries charged in cold weather, especially below zero is a challenge and having extra batteries is worth the expense. Most of these sets come with a tote that keeps them together and offers extra room for a couple of indexes for tips and bits. I suggest at least one set of standard drill bits, one of paddle bits, one of hole saws, one complete driver set and a set of masonry bits.

2) Power Saw. A 71/4″ power saw is the standard and they are part of the basic tool kit. They are also one of the tools that come in both battery and AC models although I have never seen a battery model that was even close to a hard wired saw in terms of performance. I happen to prefer a worm drive version, but this saw, while a monster for mass cuts and dimensional (green, rough sawn lumber), is tricky to operate. Because of it’s off set blade sighting it takes some getting used to and due to the gyroscopic pull of the saw it has a tendency- even for skilled carpenters- to cut off it’s own cord on occasion.

3) Table Saw. For sheet goods and rip cuts a table saw is a must-have tool. Especially if you have any intention of making furniture/cabinetry or any type of finished piece where precise cuts come into play. I have a large, three phase table saw that stays in the shop, but most of the work I do is on a much smaller 10″ portable which handles quite a bit of work for its size. These saws can be quite dangerous for newbies, especially when working on small pieces, but properly handled they are one of the most reliable and easy to use tools you’ll ever work with and a pleasure to have when required.

4) Sawzall. This is the ultimate demolition tool and one of those most frequently abused by telegenic, miniature female, HGTV hosts. It looks like a miniature chain saw but rather than featuring a circular chain it is a reciprocating (back and forth) fixed blade that operates like a jig saw. This saw allows you to cut into blind spaces, make plunge cuts through walls and floors, get into hard to reach locations, etc. the drawbacks are that it is like cutting with a live animal. If it hooks up or binds it can jerk out of your hands, it throws debris- and in demo it’s almost always filthy sawdust and petrified vermin droppings- and it has a tendency to drop blades whenever it feels like it because the fastening system is based on an allen screw that vibrates loose no matter how tightly you bind it. It also has a propensity to find hidden electrical wires in walls, so make sure to avoid the older all metal versions in favor of a heavily insulated newer model.

5) Miter Saw. This is the one saw that can turn a hack into a journeyman carpenter. It cuts precisely by holding your stock against a fence and adjusts to cut at any angle including bevel cuts. You can frame and trim with this saw and if you take your time with each cut you can turn out multiple pieces with factory precision. It’s the one saw that only gets better the bigger you go and if you can afford it the larger the better. This saw has one drawback and that is the overconfidence people tend to have when using it. NEVER, EVER use this saw to cut without having some sort of stand or bench to properly rest the piece you are cutting. I once watched a young carpenter trying to lever the piece against the table while cutting only to sever his index finger when the weight of the stock pulled it back down and he was unable to keep the portion he was cutting in place. Ouch.

6) Compressor. I debated whether to include this one because it requires an incredible number of additional tools to hook up to it to become useful, from nail guns ( I rarely use them, but by elbows tell me I should start) to impact wrenches, to sprayers to foamers, but time and experience has proven that between the inflation attachment and the little piece I use to blow dust out it’s one of those tools that can’t be replaced by anything else when you need it.

7) Dremel Tool. I think this small, hand held rotary tool is one of the most innovative little creations known to man. If you ever have anything that needs to be done on a level that requires reading glasses you are going to want to have one. It features a spinning arbor that can be used to hold fifty or more attachments from cutting bits and grinding heads to sanding discs and polishing tips. It gets into places no larger tool can reach and with speeds that no hand tool could ever hope to replicate. This is also one of those tools that works across disciplines as we use it as often for crafts as we do in maintenance and carpentry. Makle sure you get a large selection of attachments for this in order to get the full use out of it.

8) Disc Grinder. They love to use this tool in movies because whenever you see it, there’s a shower of sparks flying in the air around it. It cuts, it buffs, it polishes, it sands, it even grinds. The variety of discs available guarantee that no task shall remain undone once properly employed. It does what a bolt cutter does, what a whetstone does, what a sander does, only way, way faster.

9) Belt Sander/Orbital Sander. These are your finishing tools and they will take care of making even the roughest job look pretty nice when all is said and done. I like sanding by hand using a block, I do and I think that everyone should try this technique whenever you’ve got some sanding to do, but if you have a large piece, if you are doing a number of pieces- we make rock maple cutting boards for sale during the winter months- you can put a 7 year old on one of these things safely and for hours with little or no risk and always turn out a beautiful finished product, every time.

10) This one is a toss up. I am torn between three tools, each one great, each one used far less than anything else on the list above, each one geared towards a specific material. I leave it up to the reader to choose-

Multi-Tool. I picked this tool up about three years ago and I’ve used it half a dozen times. In each case there was no other tool that could do what this one does. It is not cheap and it’s so new I haven’t seen a used one up for sale anywhere. It has the ability to offset cut (cut under something without touching the thing in front) as well as cut a multitude of different materials from wood and metal to ceramic and plastics, each one without issue. It’s small enough for any size hand, fairly risk proof and comes in a great kit box filled with attachments when purchased new. Very cool tool, still not sure if it should be the final choice for the list.

Port-a-band Saw. This is one for metal working in places where the stock is fixed or when you don’t have access to a metal shop. it cuts rebar and angle iron like a cheese knife and is great in demolition where metals are present. Again an almost specialty tool, but one that beats the ever loving hell out of a hack saw.

Rotary Hammer. If you work with stone, masonry or plan on removing concrete in finite quantities, this is the tool for you. We live in an area that is boulder strewn and rock filled and it has saved me more time in fencing applications than I care to count. One hell of a tool that will jar your teeth loose if you spend much time using it, but once again, light years ahead of a cold chisel and hammer.

Audel’s Millwright and Mechanics guide will be needed. With that guide and your tool list you could rebuild a country.

I’ve everything but the Multi tool I am going to guess by Fein since they make some of the best tools. I am partial to Bosch for my sliding compound miter and sawzall and Dewault for my cordless and 7/14″ skill saw. Powermatic used to make a stationary great table saw, mines over 20 years old, but you can find one Delta Unisaws quite often available used, be cautioned they are a bear to move. I used to deal in tools running a specialty woodworking store out of Cambridge, you would be amazed at some of the shops many non-professional wood workers have in their home shops better than most professionals. As people have become less skilled and more lazy I think you will be able to pick up used tools fairly cheaply. I tend to lean toward the older tools they except for cordless, they are usually better built. Although I have never been disappointed with any German tool that I have purchased, new or old.

Bob.

Great list. Screw gun and skil saw change everything. Chop saw, compresser and grinder would be my next 3. With these 10 and a bobcat, you could build a civilization

Pretty good list of the basics, the only item I would differ on would be the Port-a-band Saw, it’s only item on your list that I don’t have. I can do everything I need as to cutting metal with a metal blade on a Sawzall or a Die grinder and both can get into tight places a Port-a-band Saw cannot. I would say a drill press would be more important. Yes you can use a hand held drill but there are times a hand held is just not going to give the accuracy you need.

The one item not on your list that I use on just about every project and that is a Shop-Vac. They’re an absolute must have.

Over the years I’ve been transitioning slowly away from nails/nail guns and more towards screw guns and screw type fasteners; yes more expensive but there are offsetting advantages. I can’t tell you how many times I’ve locked something in place with a shit-load of nails using a nail gun and then later needed to change/remove what I had just put in place. It’s too easy and fun to put too many nails into something with a nail gun. With screws you simply remove the screws and you’re good to go. And with screws you have an amazing array of options.

Wow. Thank you, HF. This is extremely useful.

great list,got everything except the rotary hammer.

one tool i don’t have but want is a flux core welder

Grinder should not be used in place of a whetstone. It risks detempering the metal and ruining the blade.

Good blades need to be sharpened only on appropriate stones or ceramics.

I recommend the drill be 18 volt and not 12.

A power planer comes in very handy at times.

Excellent, thoughtful post, as always. Maybe a bit off topic, but the only power “tool” I’d like to add is not really a tool, it’s a sharpener. A belt(1/2″) electric knife/tool sharpener. Work Sharp is the most unbelievably best sharpener I’ve ever seen. I am an “edged tool” junkie and I’ve always had a tough time sharpening my knives. No more! This little gem will sharpen knives(razor sharp), scissors, machetes, shovels, virtually anything with an edge. A bit pricey, but for about $150 you can buy the sharpener and some replacement belts.

If you do a lot of metal work, a metal reciprocating cut off saw comes in very handy (ie for cutting tube and pipe to length quickly and accurately).

Ragman – I almost mentioned special belt sharpener for knives, as they do indeed work. But as a knife collector, I would not use a belt sharpener myself.

A spyderco will get knives razor sharp, with little effort. And I worry about scratches from belts, and it is easy to get the bevel off center with a belt if you are not careful.

llpoh said:

“If you do a lot of metal work, a metal reciprocating cut off saw comes in very handy (ie for cutting tube and pipe to length quickly and accurately).”

Cutting tube and pipe can and should be done just as fast with the appropriate tubing/pipe cutter. Very clean cuts. Reciprocating saw makes a mess.

I missed my chance to post this on the tool bucket thread but these tools take up little space, offer easier and quicker use than hammer and tool. They are made in ‘Murika by ‘Murikans with ‘Murikan resources. You can set an entire house full of finish nails in a few hours and never touch a hammer.

[img [/img]

[/img]

[img [/img]

[/img]

IS – having been responsible for the cutting of literally thousands, probably tens of thousands, of MILES of pipe and tube in my life, I beg to differ.

I used metal band saws, mostly, but same difference re the reciprocating saw. The accuracy, speed, and repeatability are unmatched. Plus the mess is minimal, as the cut is made over a swarf collection bin. Large metal slow rotation cut-off wheels can do the same thing.

No offence, but you got this totally wrong. This is one of my fields of expertise. No kidding. I know more about cutting, notching, punching, welding, and drilling pipe and tube than anyone you probably have ever met.

Context llpoh. Context.

I assumed you were talking about what the average person/DIY’er/semi-pro handyman might be using. You know….those who might be reading this. I somehow doubt that most here will be cutting MILES of pipe/tubing. How many average homeowners are going to have or even need the equipment you’re talking about?

A good tubing/pipe cutter will do for 99.9999999999999% of the folks here.

Llpoh, that’s funny. You can’t imagine life without a cut off saw, because it’s part of your everyday life. That is me and my grinders. My guys sharpen machetes, rock bits, weighted shovels, whatever they have to do that day. Now that I look at your example, I realize most people wouldn’t need a grinder that often. They save me money six days aweek

IS/Star – But we are talking POWER tools!

But I get your point. I have built a number of racks,benches, fences, gates, etc. where my little power metal cutting saw came in handy. And the thing is, when building stuff, when the original parts are cut to accuracy of a poomteenth of an inch, everything else goes easier.

I was more disagreeing with IS’s comment re speed and cleanliness. Those points were not quite right. Re whether folks can live without it, almost all can. As y’all rightfully said.

I am a crappy tradesman. But I have found with lazer level, digital level, and very accurately cut starting point, I have some small chance of getting things square and level. Because I have no chance of fixing things once I have fucked up – things just get worse and worse.

For breaking concrete I have the large hilti 1500-AVR Breaker I also have various other Hilti hammer drills [/img]

[/img]

[img

If I do any type of metal cutting where I need accurate cuts I use the Milwaukee 14” chop saw [/img]

[/img]

[img

Ll: the sharpener comes with a guide that even a senile old boomer (me) can use. I like the 6000 grit belt for putting a razors edge on my kitchen knives.

Lloph,

For sharpening I prefer the Tormek sharpening system, slow turning whetstone the will not over heat the metal with a strop on the other side. I can get a a razor’s edge on just about anything with my diamond stone and strop when I am not in the shop. It does not replace a grinder but it is much better for sharpening. Sharpening your tools is cathartic moments when you get your mind set to start a project.

Bob.

Bob/Ragman – I use the Edge Pro and the Spyderco Sharpmaker, combined with a multistrop and diamond paste. I understand the Wicked Edge system is good, too.

I am unfamiliar with the Tormek. It is expensive by the look of it, but slow turning is good. What I read seems to indicate it will not do small knives, but I may have incomplete info.

The belt sharpeners are pretty good. The new Ken Onion looks great.

God bless whomever invented the Dremel tool… it has made us gunsmiths more money that I would have thought possible…

Not because we find it a useful too. It is. I use it to polish pistol and revolver actions with Cratex bits, and the wee buffing wheels (with green polishing rouge) do a great finish job… other stuff too, like cleaning out hard to reach places in the mortice area of rifle stocks, etc…

But because amateurs get ahold of it and, not knowing what they’re doing, completely wreck and fuck up firearms so badly, they usually bring it to us to fix. The whole “Well, I’ve got a Dremel tool! I’ll just do it myself!” Uh huh… good luck with that, Cleetus…

Out of every 100 guys who try to “fix” or modify their firearm with a Dremel, I’d say maybe 3 or 4 don’t fuck it up, and of those 3 or 4, one would have the talent to do a good job…

But hey.. I’m the last guy who would advocate against Dremel tools being used on firearms by folks who don’t know what they’re doing! Keeps me employed… job security and all that. 🙂

[img [/img]

[/img]

[img [/img]

[/img]

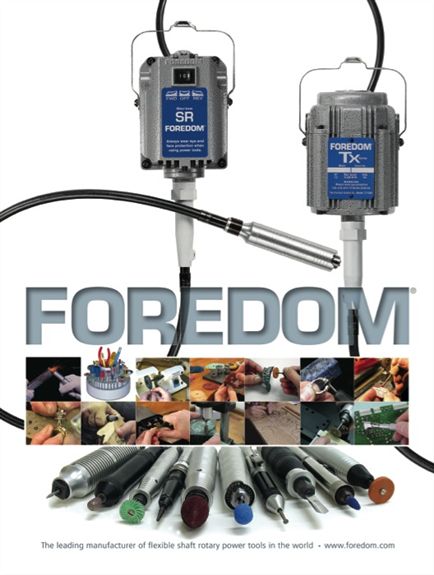

By the way, in case anyone is looking for something like the Dremel, but with more beef, I recommend the Foredom.

Basically a Dremel is a handheld tool with a motor in it with interchangeable bits.

A Foredom is a much larger motor that hangs from a support and has a long flexible shaft that takes interchangeable bits.

Both have their uses, the Dremel being more portable, the Foredom being an industrial quality tool that will outlast the Dremel, but is not nearly as portable…. Foredom’s also cost much more than a Dremel, so there’s that…

http://www.foredom.net/index.aspx

[img [/img]

[/img]

Dammit…

Try one more time…

[img [/img]

[/img]

Billy – that thing looks like something they shove up your ass during a colonoscopy. You sure that is a household tool?

Llpoh,

Heh… funny.

Foredom’s are mostly used in the woodcarving, jewelry and gunsmithing industries… where machines have to run long periods of time and have to last.

I’ve burned out a couple Dremels in my day. They’re good for what they are, but they can’t take daily hard use and last for years like the Foredom can. Even then, the Foredom can be repaired right there if you have the spares for it on hand. Most people who burn up a Dremel just go buy a new one.

Plus, a Foredom packs 1/4 horsepower. For a rotary tool, that’s some beef…

If you had a professional need for one – or just like really well built nice stuff – you could justify the expenditure for a Foredom. They are several hundreds of dollars for the motor, extension, foot pedal, stand, bits and all the other little add ons and doodads that make it worthwhile…

Correction… the most a Foredom has is 1/3HP. Not 1/4 like I said…

My bad. Carry on.

Anonymous says: Correction… the most a Foredom has is 1/3HP. Not 1/4 like I said…

What a disappointment.

What a disappointment.

I know, right?

Because, like, since 1/4 has a 4 in it and 1/3 has a 3 in it – since 4 is higher than three, that means the 1/4 is more than 1/3… so it’s better…

[img [/img]

[/img]

You got the joke, your a cool guy, Billy

You got the joke, your a cool guy, Billy

[img [/img]

[/img]

Ah crap…

Didn’t show… it’s supposed to be “Whose awesome? You’re awesome!”

Try this again…

If it don’t fly… then whatever… it’s all good…

[img [/img]

[/img]

I’ve been wanting to get a dremel tool and I appreciate your critique here, because I’ve yet to figure out what I’d use it for but it seems like a versatile tool.

What about plumbing tools???? I say the right tool for the right job. I certainly have had to improvise in my life, but the right tool would have saved a lot of time.

Homer,

Sorry, I got nothing for ya… I can do a great deal with steel and wood (actually, most metals and wood), but when it comes to plumbing, I got zero experience.

I mean, I guess I got some transferable skills – soldering metals together, cutting metals to length and drilling holes and shit… I’d have to practice some before before I tried it for real, to learn how shit reacted and I don’t burn the fookin’ house down around my ass…

I wouldn’t know what’s best or whatever when it comes to plumbing tools, either…